Integrated digitization solutions

The topic Industry 4.0 continues to dominate machine tool building right through into the new year, with DMG MORI developing with ever growing momentum into a turnkey partner. CELOS, for example, offers a modular 360° solution portfolio for integrated digitization of a factory – of machines, processes and services.

From strength to strength through digitization

“What is the good of horizontal integration in digital value chains if the Internet-enabled ERP system knows nothing about what is going on in production?” Dr. Holger Rudzio, Managing Director of DMG MORI Software Solutions, does not ask this question without good reason, because he sees the shop floor as the focal point of all digitization. In his view, the great benefit lies in the fact that digital transformation can be undertaken gradually, i.e. “bottom-up” instead of “top-down”, from the machining process to digital workflows and on through to the complete networking of the digital factory. One project after the other – and from strength to strength!

Digitization “Toolboxes” for large and small manufacturers

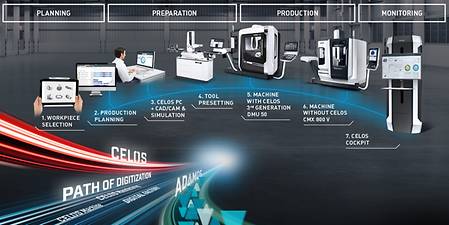

This perspective is reflected in the “Path of Digitization” that DMG MORI has declared as a mission statement for itself and its customers. It is a guiding principle that has recently been expanded enormously to include a multitude of digital innovations and pioneering projects. From January 2018 onwards, “digital factories” will be set up in the larger DMG MORI showrooms, where they will demonstrate live for customers the added value of horizontal integration.

Digital toolboxes are being created at DMG MORI through innovations and futureorientated initiatives. These will enable both a simple and harmonious entry into digitization for smaller companies while at the same time offering large companies integral and modular operability.

Consistent digitization of workflows

As of spring 2018, the focus of CELOS version 5.0 will be on end-to-end digital workflows – from planning to preparation and on through to production monitoring. The CELOS APP Package “Digital Planning“1 , for example, enables efficient organisation of orders subject to the most diverse requirements. The Production Planning APP offers users the decisive advantage of more efficiency and reliability on the shop floor. According to Dr. Rudzio, the aim is the integrated connectivity of ERP systems, digital production planning and terminal-controlled shop floor manufacturing. “When combined with production planning, such consistency adds up to continuous process optimisation”, says Dr. Rudzio. This in turn reduces setting up and idle times and ensures a sustainable boost in productivity. Added digital transparency will also result in increased planning reliability.

1Digital Planning enables end-to-end planning of production orders and includes the CELOS APPs Production Planning, Job Scheduler, Job Manager and Job Assistant.

Production planning advanced planning & scheduling

Highlights

- Intelligent planning tool for production

- Higher transparency for increased on-time production

- Optimisation of throughput times and batch sizes

- Visualisation of capacity reserves

- Planning of maintenance

- BDE/MDE feedback

- Interfaces for transfer of orders from ERP systems

“Digital Tooling“2 is another workflow package. All tool information needed for the production process can be managed centrally with this CELOS APP package: NC programming and simulation as well as tooling, scanning and loading, whereby different systems can access the tool data simultaneously. In addition, all process-related data are stored in a central tool management database, ensuring a transparent and seamless tool history.

2Digital Tooling realises integral tool management and includes the CELOS APPs Tool Handling, Tool Agent and Tool Analyzer.

Digital tooling - Three CELOS APPs for integral digital tool management

Tool agent

- Generation and management of digital tools

- Setting of tool parameters

- Capture of presetting data

Tool analyzer

- Analysis of recorded tool and process data

Tool handling

- Improved handling of physical tools (loading & unloading)

- Identification and adaptation of digital and physical tools

Monitoring with added value

To provide more transparency in production, the APP Package “Digital Monitoring”3 visualises all key information of the digital factory. The CELOS APP Condition Analyzer offers the capture, storage, analysis and visualisation of machine sensor data. The CELOS APP then enables subsequent analysis of several machines, e.g. for early recognition of machine failures. The Performance Monitor also visualises current machine availability and efficiency independently of location. In this way the CELOS APP creates transparency and control possibilities with regard to basic manufacturing parameters – so-called Key Performance Indicators (KPIs).

There are also a number of expansion options. With CELOS PROtab, DMG MORI brings a mobile assistant into networked production. DMG MORI customers will in future also use CELOS functions on older machines and machines from other manufacturers with the aid of this industrial standard. In addition, live images can be imported into chat conferences with the new serviceCAM in combination with the NETSERVICE 4.0 APP.

3Digital Monitoring visualises all relevant process and machine information of a digital factory and can include the following CELOS APPs: Messenger, Condition Analyzer and Performance Monitor. Data from the APPs Production Planning and Tool Analyzer can also be visualised and the APP Cockpit can be used as the visualisation screen (dashboard) for all the APPs mentioned.

Digital monitoring – The entire production process at a glance

Cockpit

- Visualisation of relevant machine data from the CELOS APPs Messenger, Condition Analyzer, Performance Monitor, Production Planning & Tool Analyzer

Messenger

- Increase in productivity through immediate detection of idle times

Condition Analyzer

- Capture and analysis of machine data with direct feedback for maximum machine productivity

Performance Monitor

- Location-independent capture, analysis and visualisation of machine availability and efficiency through direct feedback from production

Everything at a glance

CELOS COCKPIT is the bridge between all machines in the production environment. This is where all shop floor-relevant information comes together, from both DMG MORI machines as well as third-party machines. It provides users with a holistic overview of the status on the shop floor – and, with the respective digital workflows from DMG MORI, even information about orders and failures (including bottlenecks, idle periods, causes and remaining runtimes).

As of April 2018, all DMG MORI machines with SIEMENS, HEIDENHAIN and MAPPS controls (except the SLIMline machines) will be available with CELOS version 5.0. Existing machines with older CELOS versions can be upgraded to the latest software standard.

The update to CELOS Version 5.0 is carried out by DMG MORI Service using an update stick. Data and communication settings remain intact. Every customer receives basic training in the new features when the new version is put into operation.

ADAMOS facilitates turnkey digitization

DMG MORI has implemented a key element of the CELOS digital factory with its digitization of the shop floor. To further expand digitization, DMG MORI has established the IIoT initiative ADAMOS in collaboration with partners from the fields of machine building and IT.

“ADAMOS is an important part of our “Path of Digitization”, because it allows us even greater freedom to determine and actively shape digitization ourselves”, is how Dr.Rudzio explains the strategic importance of the IIoT initiative.

He compares the baseline situation with that of the PC world: “Where “Intel inside” is involved, we have ADAMOS – and where Windows operates on computers, we install CELOS.” DMG MORI is working with strong partners, such as Dürr, Zeiss, ASM, Engel and Software AG in the ADAMOS initiative, with more partners to follow.

DMG MORI started off with a CELOS APPbased control and operating system. It is already possible to plan and visualise databased processes completely from end to end in a factory with CELOS manufacturing. Thanks to ADAMOS, CELOS can now be developed into an open network and digital marketplace for the machine building industry. Dr. Rudzio sums it up: “We can now offer our customers digital services for all aspects of machines, we can digitize the entire production process chain and, thanks to ADAMOS, we can successfully design the processes for our customers integrally from end to end with a 360° approach!”

ADAMOS - ADAptive Manufacturing Open Solutions

Mechanical engineering industry shapes digitalization

Facts

- Global Alliance: DMG MORI, Dürr, Software AG, ZEISS, ASM and Engel pool their resources in ADAMOS for Industry 4.0 and are ready to welcome further partners

- Open Platform: The ADAMOS IIoT-platform is manufacturer-neutral, linking cutting edge IIoT technology and advanced industry knowledge

- Broad App Portfolio: The ADAMOS App Factory Alliance focuses on the technological expertise and industry knowledge of the partners for rapid joint development of apps

- Digital Marketplaces: The partners promote their digital competence to their customers and individual marketplaces under their own brand identities (for example CELOS powered by ADAMOS)

- Strong Set-up: ADAMOS GmbH and the ADAMOS App Factory Alliance launched on 1st October 2017 with around 200 experts, 5 digital marketplaces and more than 30 apps

- End-to-End: With ADAMOS, DMG MORI offers its customers, partners and suppliers a complete digitalization strategy