Perfectly controlled steam pressure for energy generation

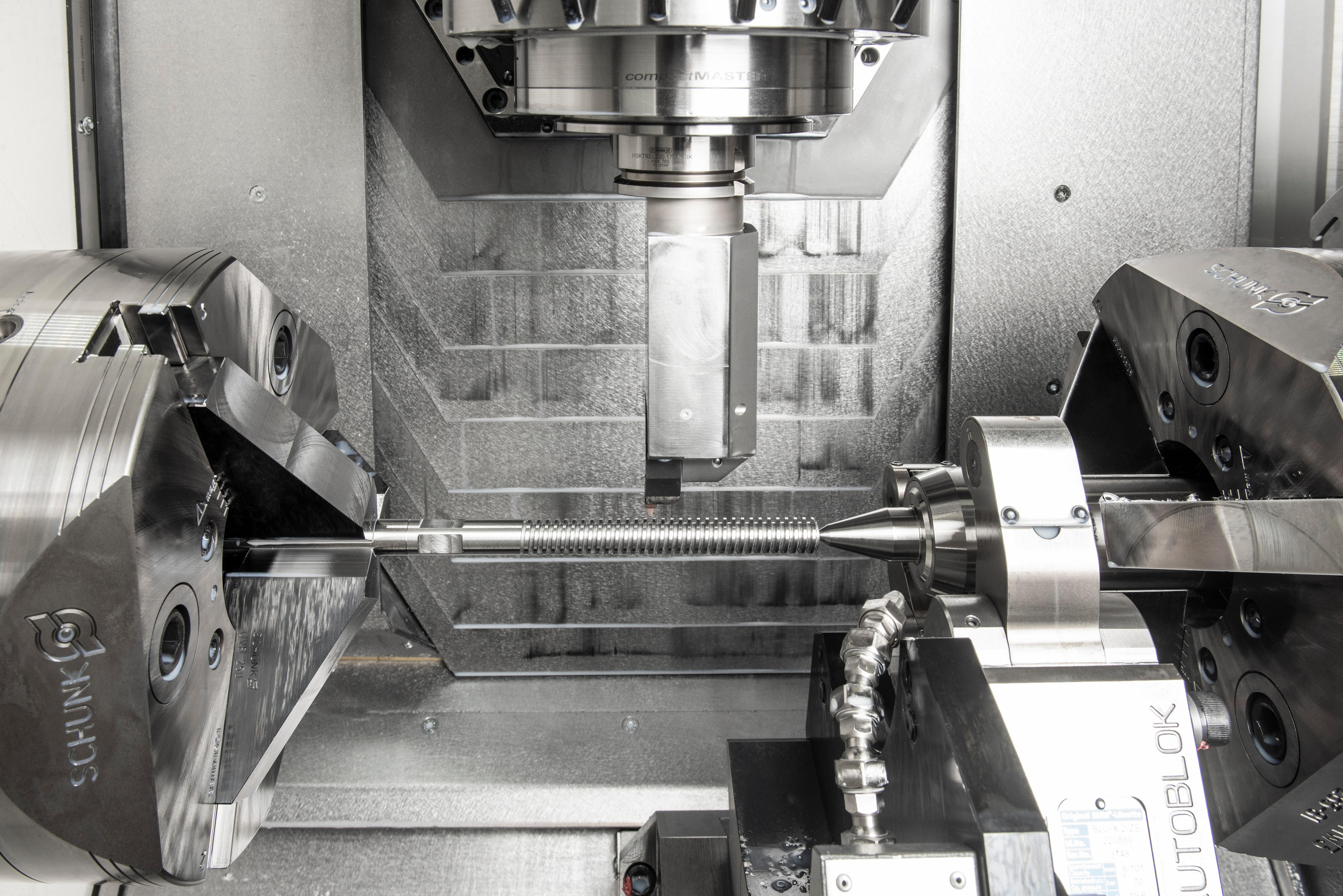

Precise, passionate, professional – HORA has been a reliable partner for durable and low-maintenance control valves since 1967. Many customers from all over the world now rely on the engineering skills from Schloß Holte-Stukenbrock. Whether in the energy sector, gas infrastructure, process technology, building technology or other industries, the 320-strong team puts the requirements of its customers first. The company focuses on quality, safety as well as efficiency and masters the challenges of a competitive market on a daily basis. HORA has been relying on 6-sided complete machining since 2008 in order to be able to produce demanding workpieces competitively. It all started with three CTX gamma TC machines from DMG MORI. From 2021 to today, six CTX beta models have also been installed, five of them also in the turn & mill version. With the latest acquisition, a CTX beta 1250 TC, HORA is setting another milestone. Thanks to DMG MORI's exclusive Multi Threading 2.0 cycle, the machine produces spindles including high-precision trapezoidal threads with a 50 percent increase in productivity.

Precise control valves from a single source

Many power plants generate energy by using steam to drive turbines that drive a generator. There, the kinetic energy is converted into electricity, just like in a dynamo. To do this, the steam must be regulated to the correct pressure and steam quality via a complex system of pipes and valves. This is precisely where HORA comes into play with tailor-made control systems. “We know the technological, commercial and organizational challenges of our customers very well,” says Andreas Petker, Head of Machining. “Every project is unique, so we are constantly faced with new challenges from development to production and final assembly.” This is where HORA's strength is evident: “Our innovative solutions ensure smooth operation, optimize processes sustainably and increase performance.”

6-sided complete machining on DMG MORI turn & mill centers

As the control valves consist of a large number of sophisticated components, their precision plays a significant role in this performance. “That's why we only use high-precision machine tools,” says Andreas Petker, referring to the machine park with a total of ten turning centers from DMG MORI. “Complete machining in particular is essential for an economical and quality-oriented production.” This explains the high proportion of turn & mill centers. Larger components are machined on three CTX gamma 2000 TC, which HORA opted for at the time because of the user-friendly ShopTurn programming. For Waldemar Benks, who is responsible for process design in the machining department, this is an important factor in day-to-day business: “In these cases, we program the components exclusively on the machine, so ease of use is crucial.”

CTX beta TC for maximum component diversity

The CTX beta TC models purchased at a later date offer space for an extremely wide range of components. “Thanks to their versatility, we can use these machines to capacity practically all the time,” explains Andres Petker. One of the CTX beta 1250 TC also has a Robo2Go, which processes orders with small batches in unmanned shifts. “However, the rule is individual parts that have to be processed correctly in the first attempt because the raw material or cast parts are procured specifically for the order,” emphasizes Andreas Petker. HORA meets the high standards in production with well-trained specialists – including from its own training workshop. A lathe from DMG MORI, a CTX 350, is also used here.

50 percent more productive thanks to multi-thread cycle 2.0

The CTX beta TC turning centers are programmed centrally via a CAD/CAM system. “We have equipped all machines in the same way so that we can process the programs flexibly at any time,” says Waldemar Benks, describing the workflow. The latest model also has a steady rest and the DMG MORI Multi Threading 2.0 cycle. “This special feature contributed significantly to the purchase decision.” The technology cycle allows free definition of contours, pitches and threads. “This made the machine particularly interesting for us, because we saw a good way to make the production of spindles with demanding trapezoidal threads more productive,” adds Andreas Petker. The result has confirmed expectations. The increase in productivity is 50 percent. “This is due to both the simple programming using the technology cycle and the special tools that we developed for this application together with the tool manufacturer Paul Horn,” says Waldemar Benks, looking back on the extensive project. The tools work with low vibration and therefore offer longer tool life and better process reliability. “On the one hand, this is more effective and, on the other, we can now leave the machine to work unattended.”

Long-term competitiveness through process integration

Andreas Petker is delighted with successes such as this process optimization: “Innovative machining strategies offer great potential for integrating more and more processes into one workspace.” This is why HORA is planning further investments in complete machining on turn-mill centers in the future. "We are experiencing a major shift in the market towards more sophisticated products with shorter delivery times, partly due to the increased expansion of renewable energy generation. “With the appropriate production capacities and a high degree of flexibility and productivity, we will be able to work competitively ”Made in Germany“ in the long term.”

Holter Regelarmaturen GmbH & Co. KG

Helleforthstrasse 58-60

D-33758 Schloß Holte-Stukenbrock

HORA